accuracy of total knee replacement

The techniques for manufacturing implants have advanced significantly over the years. We are now at a point where the implants are reliable and it is difficult to make design changes that will have a significant impact to change the period of time an implant will last for (survivorship).

We do know that poorly positioned implants can fail early or cause complications (eg. anterior knee pain from poor patella alignment)

There are 2 modern techniques that can be used to position knee components more accurately than traditional techniques.

1. Computer Aided Navigation

-

2.Patient Specific Instrumentation

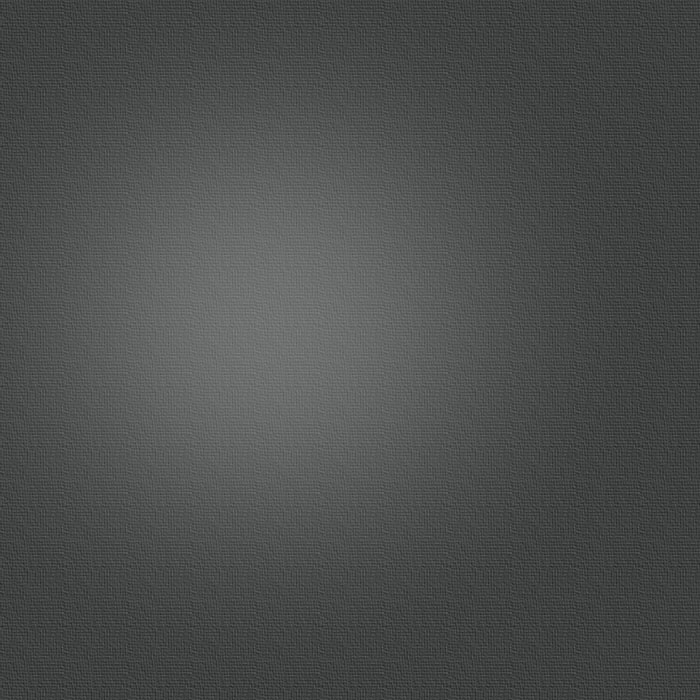

computer aided navigation

Imageless Computer Aided Navigation is thought to be the most effective method to accurately position Total Knee components. It has been demonstrated to improve component positioning in knee replacement surgery. It does, however, have some disadvantages. The surgery generally takes longer than traditional surgery (potentially increasing post-operative pain and infection risks) and extra holes need to be made in the femur & tibia (risk of fracture in thin bone).

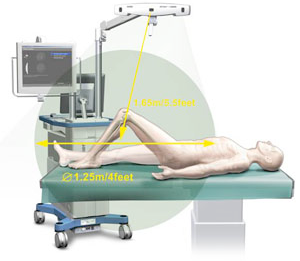

patient specific instrumentation

Patient Specific Instrumentation is a more recent innovation which allows specific tailor made cutting jigs to be produced for each individual patient. This reduces the operating time considerably and allows very accurate placement of the implants. It is thought that the shorter operating time and precise placement of components will improve patients post-operative rehabilitation, pain control, and potentially survivorship compared to traditional techniques.

After deciding to proceed with Total Knee Replacement, Mr Higgins will arrange for either a Computer Tomography (CT) scan, or an Magnetic Resonance Scan. Only surgeons with access to specially calibrated scanners can perform the surgery. Once the scan has been performed it is imported into a computer program which will allow Mr Higgins to look at different component sizes and positions. The optimum size and position are calculated and the measurements are emailed to America, currently, where individual bespoke cutting jigs are produced and sent to the UK. This process takes approximately 4-6 weeks at the moment.

modern techniques in total knee replacement

Imageless computer aided navigation machine. (top left)

Patient Specific Custom Made Cutting Blocks/Jigs. (Right)